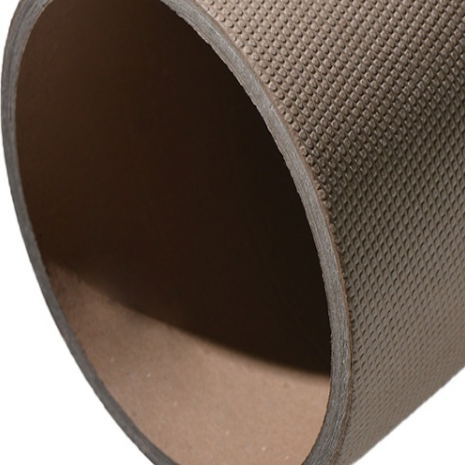

High performance paper cores with slip resistant surface for non-woven manufacturers.

Highlights:

- Various non-slip ‘embossed surface’ options designed to run at high speeds

- Maximum strength and dimensional stability against radial pressures engineered for high speed winding processes

- Maximum straightness engineered for a smooth start-up winding

Textiles, fabrics and non-wovens are sensitive products. They place high demands on the winding core. That is precisely where we at Allions Together with you, we have developed paper cores which correspond exactly to your individual requirements in the textile industry. With our high-quality cores of especially robust materials you can be assured: your goods will arrive undamaged at the destination.

Advantages:

- Fast and wrinkle-free start-up winding

- Wrinkle-free transport

- Optimal adhesion of the fabrics to the paper core surface

Our convolute cores for wrinkle-free transport

Are you looking for cores which have a particularly high bending strength and therefore enable a winding process without wrinkles. Then you can rely on our convolute cores. Upon request you can also get our convolute cores with a wound-on flap for a soft transition to the fabric. An axially applied, two-sided adhesive tape enables a particularly fast and wrinkle-free start-up winding process.

Our convolute cores are available in the following dimensions:

- Length: up to 2.32 m

- Inner diameter: from 17 to 120 mm

- Wall thickness: from 1.5 to 15 mm

Our spirally wound cores for extra-wide textiles

Do you wish to wind extra-wide non-wovens and geotextiles? Then your best decision would be our spirally wound cores. They convince with excellent characteristics of concentric rotation. Embossed or coated with crepe, our cores furnish perfect adhesion of your fabric to the surface of the core. Our cores are also available with a water-repellent surface for outdoor applications.

We supply our cores in any length and with almost all desired inner diameters.